With the development of LED lighting and the high demands from consumers, LED chip manufacturers continue to improve and innovate. The development of CSP has several new advantages, no substrate, solder-free wiring, small size, and high optical density.

CSP, or Chip Scale Package, is defined as a LED package with a size equivalent to a LED chip, or no larger than 20%. The CSP product features integrated component features that do not need soldered wire connections which reduce thermal resistance, reduce heat transfer path, and reduce possible failure points.

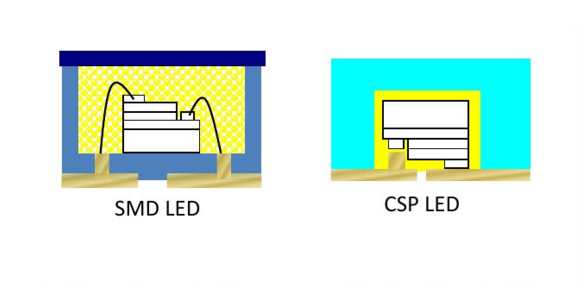

Traditional SMD LED chips are mounted on a holder and connected to the PCB by alloy wire. The electrical current flows from the PCB board and through the alloy wire to power the LED chip. During use, too much heat or a surge in current can damage the wires resulting in LED failure. CSP chips, on the other hand, can be directly applied to the PCB effectively shortening the heat flow path to the substrate and reducing the thermal resistance of the light source. Under the same current, CSP chips have higher intensity and lower current consumed compared to SMD chips. And since the CSP LED chip has no chip holder or wires connected, two possible LED failure points are removed.

Compared to traditional 2835 SMD, or the popular flip 2835 SMD, CSP chips are small in size but feature high intensity per unit with less heat. CSP is ideal for applications like LED headlights. Automotive LED light manufacturers use CSP chips to replicate the size and location of the tungsten filament in halogen bulbs to create beam patterns much like halogen bulbs.

.png?width=300&height=87&name=logo%20(1).png)